With up to 60 percent of high school graduates not finding employment or continuing their education after high school, MCC is working to change the culture in our community by utilizing our industrial trailer to bring automation alive to area students and recruiting high school graduates into the industrial automation maintenance program.

With entry-level industrial automation maintenance workers earning $46,000+ per year, this program will have an immediate impact on our skilled trades students and large-local employers who need skilled industrial automation maintenance workers.

Montcalm Community College has developed an innovative program in industrial automation maintenance needs identified by local employers. This program advances MCC's industrial automation programming and was developed using a ladder design where students will begin with foundation courses before moving into robot maintenance specific coursework. This allows non-employed students to seek employment after finishing the first year of the program

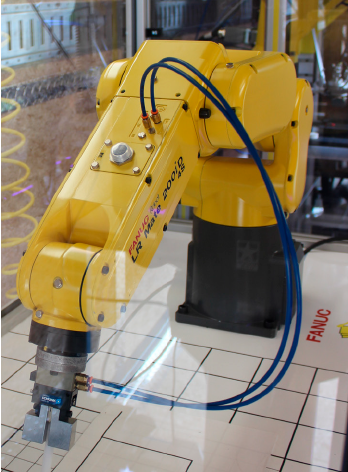

College student enrollment in industrial programming and robotics has remained low during the past few years. To increase awareness of career opportunities, MCC has facilitated high school tours at local manufacturers, promoted MCC's industrial labs, and participated in job fairs with high school students. MCC ourchased and equipped a touring skilled trades trailer, which contains FANUC and ABB robots, and Allen Bradley RSLogix PLCs. KUKA robots, Sieman PLCs, and an EMCO CNC mill can be added to the trailer for specific demonstrations.