Vehicle Electrification Systems Standards: 3-Phase Drive Motors and Generators

Vehicle Electrification Systems Standards Curriculum Description:

The Vehicle Electrification Systems Standards curriculum is provided by the Northwest Engineering and Vehicle Exchange (NEVTEX) and was developed by Central Oregon Community College (COCC) and Rio Hondo College (RHC). COCC and RHC worked together "to develop curriculum and training standards for technicians in hybrid electric vehicle (HEV), electric vehicle (EV), and Fuel Cell (FC) vehicle systems." This curriculum was developed with the intention of addressing industry needs by partnering with industrial and educational representatives to obtain input and assistance to develop:

- new approaches to prepare an advanced technologies workforce,

- licensure procedures and policies to ensure the safety of technicians, their employers, and clients, and

- collaboration between educational and industrial partners in the development of new standards and practices.

The Vehicle Electrification Systems Standards are divided into 11 topics. This section of the standards covers the topic 3-Phase Drive Motors and Generators.

The other 10 topics and a Master Acronym and Definition list are available to view separately.

3-Phase Drive Motors and Generators Description and Contents:

This section of the Standards includes the following six lesson plans: V. a - Acronyms and Definitions; V. b - Overview of HV 3-Phase Electric Machines; V. c - Induction Electric Machines; V. d - Permanent Magnet Electric Machines; V. e - Electric Machine Speed and Position Sensors; V. f - Electric Machine Testing, Analysis and Diagnostics - On and Off Vehicle. Each lesson plan covers different aspects of phase drive motors and generators. The lesson plans include a description, objectives, tools, tasks, and outcomes.

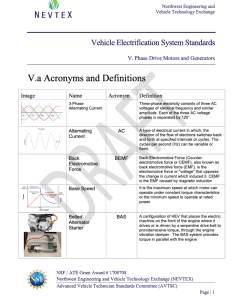

The 16-page acronyms and definitions document includes a table of images, acronyms, definitions, and alternative names for each term.

The 3-page overview document will have students “describe how vehicle electric machine propulsion, regenerative braking, and coasting modes; identify powertrain architectures and powertrain components; and define the term power density.”

The 3-page lesson plan on induction electric machines encourages students to use “various diagnostic techniques and tools” to “analyze and evaluate the condition of IM electric machine technology.”

The 3-page lesson plan on permanent magnet electric machines tasks students with identifying “powertrain architectures and powertrain components,” as well as performing tests to diagnose PM machine technologies.

The 2-page document on electric machine speed and position sensors has students “describe and illustrate how Encoders and Resolver sensor systems operate within the electric machine control environment; describe how Encoders and Resolvers are constructed; [and] analyze and evaluate the condition of Encoders and Resolvers by using various diagnostic techniques and tools.”

The final 3-page document will have students demonstrate their ability to test, analyze and diagnose 3-Phase electric machines, both onboard and off-board the vehicle, while using all of the appropriate technologies and equipment covered in the lesson.

About this Resource

Comments